Carbon ink PCB – Carbon PCB – PCB Carbon

Carbon Ink PCB are typically used to create a protective contact surface for switches, which are far more cost effective than typical alternative: hard electroplated gold.

We offer one-stop Carbon ink PCB solutions. We are Carbon ink PCB manufacturer in China.

Legend:

- Carbon PCB

- PCB Carbon

- conductive ink PCB

- Thick film PCB

- Thick film circuit board

Carbon ink PCB – Made in China

What’s Carbon Ink PCB? Carbon ink PCB, is the circuit board with carbon ink applied onto the copper pad. The carbon will be a conductor to connect two traces on PCB board, and a resistor between the traces or traces and components. The key factor in carbon ink PCB production is to control the printing, baking and resistance control. The carbon ink can be printed onto flexible circuit, rigid-flex board and rigid PCB, such as polyimide, polyester, FR-4, FR-5 and PTFE laminates. Carbon ink can offer resolutions as fine as 100μm trace width and spacing, and it is always applied for the printed circuit boards, including RF shielding, keypad, remote control, automotive vehicles, industrial engine control, welding equipment and etc.

Advantage of our Carbon ink PCB

1, Carbon ink PCB with high quality which compliance after RoHS and REACH.

2, Laser corrected is available. The Linearity error can up to ±0.02%.

3, Full experience in exporting Carbon ink PCB to European and American market.

4, The conductive ink we normally use from Asahi Chemical Research Laboratory Co., Ltd.

5, Capable of producing Carbon ink PCB up to 2000mm material in total for the longest length.

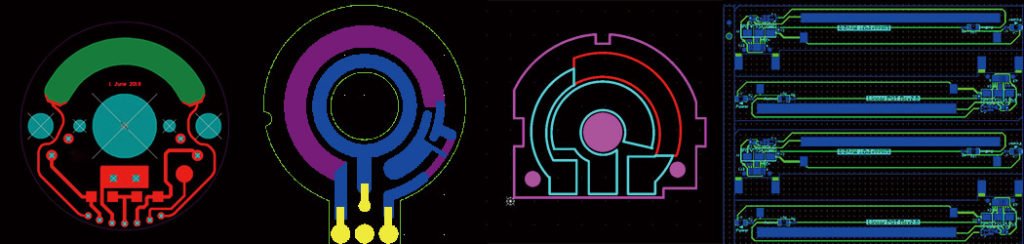

Cases we did

Asia Pacific Circuits is a reliable leading PCB and PCB assembly manufacturer in Shenzhen, China since 2002, we provides carbon ink printed circuit board (PCB) manufacturing and assembly service with ISO 9001: 2015 approval. We have advanced carbon ink PCB fabrication process control and offer carbon conductive PCB middle-volume and high-volume. Our capacity include 1-8 layer flexible carbon ink PCB, 2-12 layer rigid-flex carbon ink PCB and 1-20 layer rigid carbon ink PCB. We controls the carbon ink process quality strictly. For example immersion boards or immersion silver can not be produced with carbon ink, because if you print carbon ink after immersion silver or immersion tin, it will contaminate the PADs surface. If you print the carbon ink first and then immersion silver or immersion tin, the silver and tin will adhere to the surface of the carbon ink. So our engineers will review the Gerber after receiving from our customers, if there is a carbon ink + immersion silver or tin, we will suggest the customer change to carbon ink+ immersion gold.