When you visit a PCBA Manufacturer in China you may ask the engineer or the engineer will tell you why the component would have needed to be baked before reflow soldering.

In general, the reason for baking a component is to carefully remove all the moisture from the plastic part of the component. When a SMT component goes through a reflow oven, the temperature of the component (obviously) rises very quickly, causing any moisture inside to turn into steam. If without process of baking, it may lead some problems during inspection such as cold soldering.

When we need to bake the component ?

1) No need bake if component with sealed vacuum bags.

2) If the relative humidity level is over 20% showed on humidity indicator when open the bags then component require baking.

3) If the component exposed over 72 hours (bag opened) before reflow soldering then component require baking.

4) If the component packed with other kind bags but not vacuum bags and without humidity indicator then component require baking.

5) The recommended bake humidity for component in is 10%, the recommended bake time is 48 hours.

Extension

1) The lifespan of component is 12 months under sealed vacuum bags.

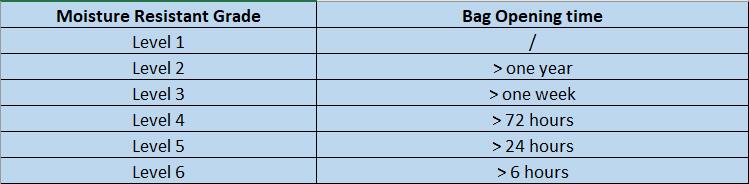

2) After opening the bag, in conditions of 30℃ & 60%RH, the component need bake before reflow soldering if based on below situation (see table)

3) If the sealed bags opened however no need production at that moment then the component need to be stored in the drying oven instantly (in conditions relative humidity below 20%).